Tyre packing machine

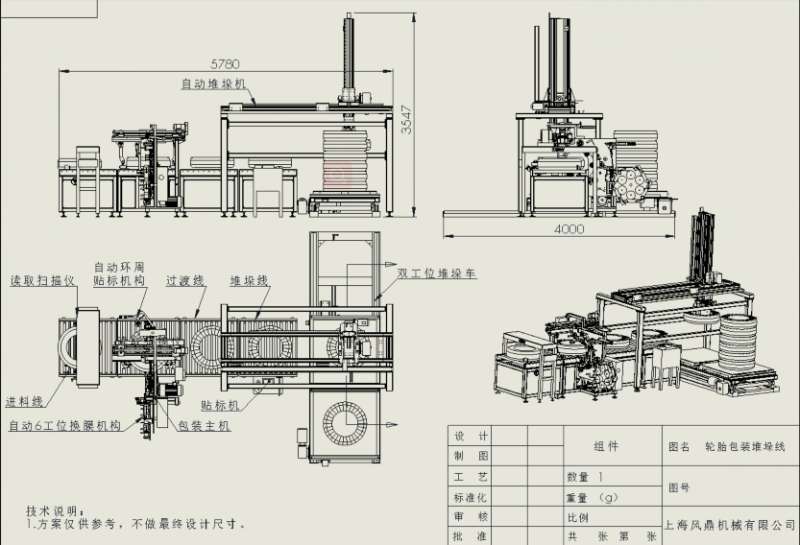

The automatic tyre packing line is a highly automated system that is designed for efficiently packing tyres into pallets. This type of system can be useful for a variety of industries, including manufacturing, distribution, and logistics.

Some key features of this system include:

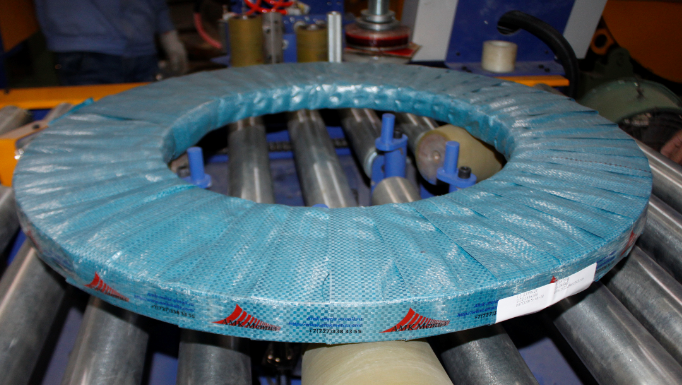

A horizontal tire wrapping machine: This can be used to wrap tyres in film or other packaging material to protect them during transportation and storage.

Information reading, sending, and tyre palletizing: These features can help automate the packing process and improve efficiency by allowing the system to track and record information about the tyres and automatically palletize them.

The ability to automatically measure the tyre OD: This can be useful for accurately wrapping tyres of different sizes.

The ability to exchange packaging material automatically: This can provide flexibility in the packing process and can be useful for different applications.

The ability to be customized to meet specific customer requirements and space constraints: This can help ensure that the system is well-suited to the specific needs of the customer.

Overall, an automatic tyre packing line can be a valuable tool for efficiently packing tyres into pallets and preparing them for transportation and storage.

These features would be present in a high-quality and advanced tyre packing line.

CE standard with international brand electric parts: This can help ensure that the line meets safety and quality standards and that the components used are reliable and durable.

PLC, touch screen, and user-friendly program: These features can help improve the ease of use and control of the line.

The ability to connect to a tyre in-feeding conveyor: This can help improve efficiency by automating the process of feeding tyres into the line.

Inverters for adjusting the speed of the ring, roller, and conveyor: This can help control the speed of the packing process and can be important for ensuring that the tyres are packed accurately and efficiently.

A stacking machine for palletizing packed tyres: This can help automate the process of palletizing and can improve efficiency.

Indicator alarms and error messages with codes: This can help identify and troubleshoot problems that may occur during the packing process.

Supportive rollers for lifting the tyre wrapper: This can help make it easier to wrap tyres and can improve the accuracy of the process.

The ability to adjust the overlap rate of wrapping film: This can provide flexibility in the packing process and can be useful for different applications.

The ability to pre-set the wrapping film tension: This can help ensure that the film is applied consistently and accurately.

The ability to adjust the ring and roller speeds: This can help control the speed of the packing process and can be important for ensuring that the tyres are packed accurately and efficiently.

The ability to adjust the packing tape tension: This can help ensure that the tape is applied consistently and accurately.

A clamper for film feeding: This can help improve efficiency by eliminating the need for manual feeding of film.

The ability to provide the ownership of the tyre packing line: This can be beneficial for customers who want to purchase the line outright rather than lease it.

A soft start and stop feature: This can help protect the line and prolong its lifespan by preventing damage during start-up and shut-down.

The ability to reset the ring to its original position: This can be useful for ensuring that the tyre is wrapped consistently and accurately.

The ability to adjust the overlap rate from 10-90%: This can provide flexibility in the packing process and can be useful for different applications.

A wrapping method using material from the material wheels of the ring: This can help ensure that the tyre is wrapped consistently and accurately.

Automatic positioning for tyre wrapping in different OD: This can be useful for handling a variety of tyre sizes.

The ability to start and stop softly: This can help protect the line and prolong its lifespan.

Rotate roll and centering roll covered with PU for product protection: This can help protect the tyres and ensure that they are wrapped correctly.

Overall, these features can help make the tyre packing line a fast, accurate, and efficient tool for packing tyres into pallets and preparing them for transportation and storage.

Automatic tapping machine

The automatic tapping device you described is a specialized machine that is designed to apply BOPP (biaxially-oriented polypropylene) adhesive tape to the surface of tyre packages. This type of device can be useful for a variety of industries, including manufacturing, distribution, and logistics.

Some key features of this device include:

The ability to automatically feed and cut the tape for different size tyres: This can help save time and improve efficiency by eliminating the need for manual tape application and cutting.

High level adjusting for different tyre heights: This can be useful for handling a variety of tyre sizes and can help ensure that the tape is applied accurately and consistently.

Overall, an automatic tapping device can be a valuable tool for efficiently applying adhesive tape to tyre packages and preparing them for transportation and storage. It is likely to be used in conjunction with other equipment, such as a tyre wrapping machine, to complete the packing process.

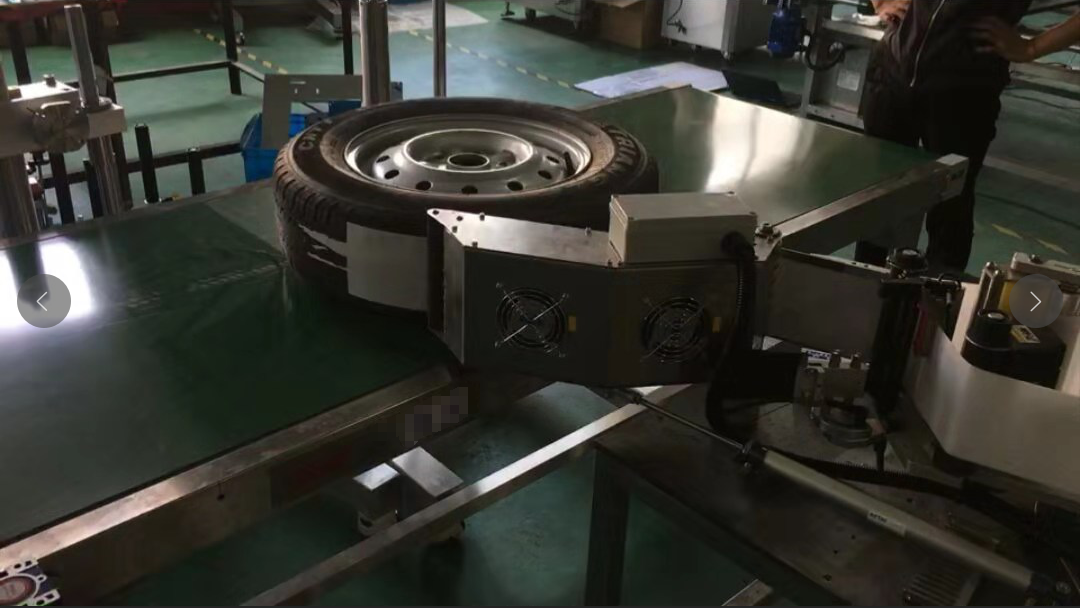

Auto online printing&attaching labeling machine

Auto online printing&attaching labeling machine

It is designed to allow for the customization and management of printing forms and information for packaging purposes. This type of system can be useful for a variety of industries, including manufacturing, distribution, and logistics.

Some key features of this system include:

The ability to edit the printing form and information with different layouts: This can provide flexibility in the packaging process and can be useful for different applications.

The ability to set and change information through a touch screen: This can make it easy to update and manage the information being printed on the packaging.

A port for receiving customer information: This can allow the system to receive and process information from external sources, such as a customer's database or management system.

Ports for sending package information to a customer's management system: This can allow the system to transmit information about the packages to the customer's system for tracking and management purposes.

Overall, it can be a valuable tool for managing and customizing printing forms and information for packaging purposes. It can help improve efficiency and facilitate communication between different systems and organizations.

The ability to interface with a field's production data system: This can allow the labeling system to receive and process information from external sources, such as a production database or management system.

PLC control and a touch screen operation interface: These features can provide a user-friendly interface and allow for precise control of the labeling process.

Software that transmits data and completes label making: This can help automate the process of creating labels and can improve efficiency.

Sensor detection of products and PLC signal processing: These features can help ensure that the labeling system accurately detects and processes information about the products being labeled.

The ability to adjust labeling position through parameter setting: This can provide flexibility in the labeling process and can be useful for different applications.

High labeling speed and a clear display of labeling count: These features can help improve efficiency and provide visibility into the labeling process.

Online automatic printing and automatic attaching in the exact position: These features can help ensure that labels are accurately and consistently applied to the products.

The use of a well-known brand, such as Zebra, for the printer: This can provide confidence in the quality and reliability of the printer.

Tire weight: 5-100kg

Tire height: 150-300mm

Tire OD: 600-1000mm

Tire ID: 150-500mm

Roller Speed:2-4m/min

Packing Speed: 30-35sec/pcs

Rotating speed: 40-100r/min

Overlap scope: 20%-90%

Air supply: 5-7bar

Power output: App.2.2kw

Power voltage: 380v/50Hz/3ph

Packing material:

Stretch film : ID: 50mm, OD: 80-120mm, Width: 60-70mm