Connect with an FHOPE Specialist: +86 13951501635

Connect with an FHOPE Specialist: +86 13951501635

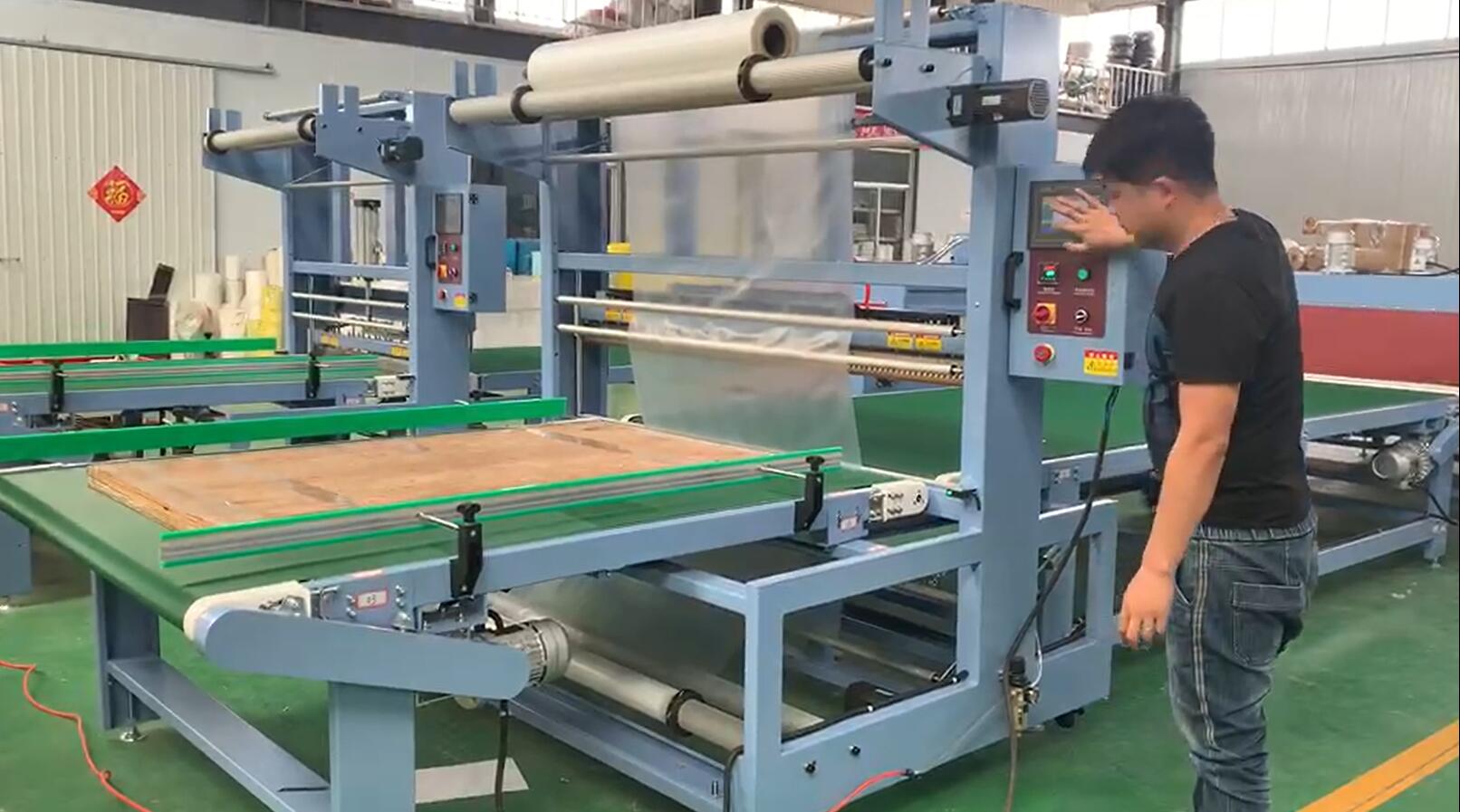

Adopting Two vertical press rolls to press the two sides of the panel after shrinking packaging and make a tidy edge.

This tight and neat package surface can be as a sale point for the manufacturers.

Three sealers fixed on the machine, instantly cut and seal three sides of the package before going into the shrinking tunnel, greatly shortened the time. The wholly sealed package does a better performance in protecting your products.

1.Sealing machine

Control: PLC and touch screem

Structure material: Plastic and Carbon steel

Packing Objects: Door panels

Length: >1000mm

Width: 600-1250mm (custiziedable)

Height: 50-220mm

Height of working table: app. 850mm

Conveyor speed: app. 4-10m/min

Packaging type: Full sealed packaging

Packing material: PE/POF/PVC .

Sealing part power consumption: app.4.8KW

Power supply: per requirement

Air Supply: 5~7kgf/cm2

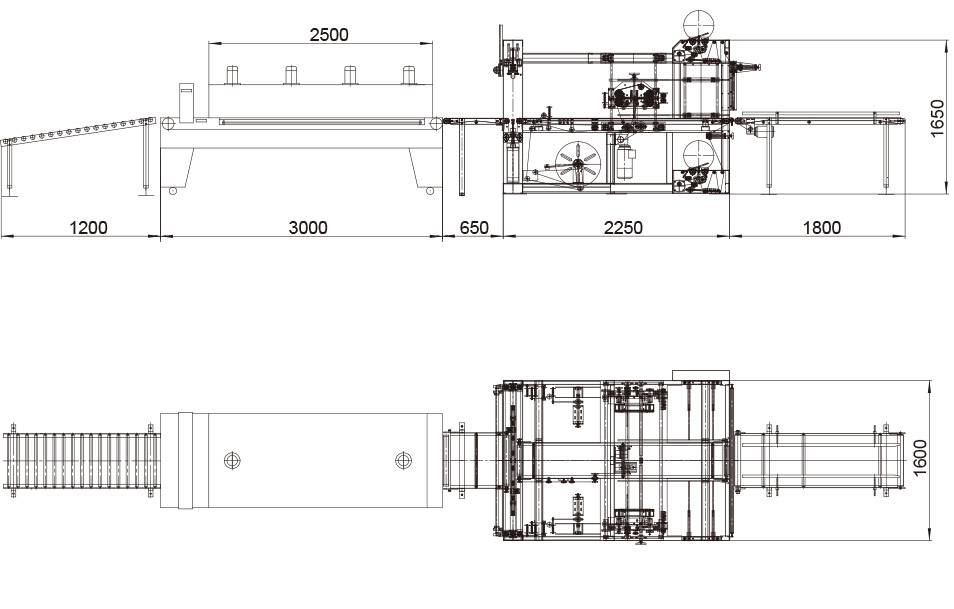

2.Shrinking machine tunnel

Structure material: PU roller and Carbon Steel

Length:3900mm

Shrinking tunnel: 3500mm

Shrinking tunnel side: W 1450mm x H300mm

Heating power consumption: App.45Kw

Calorific: 4PCS

Cooling fans: 1 Group

Drive part: Motor with geat control by inverter

Conveyor speed: app. 6-10m/min

Temperature: 50℃-230℃

Power supply: 380V

Motion type sealer door shrink packing macine including one cross sealer and two motion sealers for full-size sealing door and bagging packing, which adds the shrinking tunnel and horizontal conveyor for high efficiency door packaging.

FHOPE team offer packing equipments with international advanced and reliable high-speed technology.

1. Horizontal orbital wrapper for door

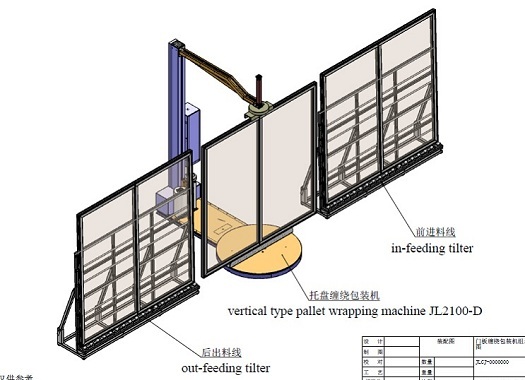

Solution= in-feeding conveyor + wrapping machine+ out-feed conveyor

Solution: Film covering machine + wrapping machine + out-feeding conveyor.

Stretch wrapping solution provides better protection for your door with full size packaging through spiral wrapping.

Bubble Film covering device adopts PE film, bubble film. cut film by sealer.

Automatic film loading Automatic film fixing and cutting for 2 rolls

1.Side gravity rollers for product loading

2.Gravity roller conveyors 800x1000 mm

3.Up&Down Air bubble film dispenser

4.Ring System for fixing the dispenser head in the exact position for changing the roll

5.Top clampper for film cutting with manual adjustment

6.The transfter Bridge betweem conveyors for short products < 600 mm

Film covering machine + top pressing down device

The vertical door wrapping machine equipped with buttom automatic turntable, adpot stretch film wrapping packaging solution. The solution to provide customers with stretch film protection for transportation and door handling.PE stretch film is used for laminating device, the stretch rate is 200%-250%.

WELCOME TO CONTACT WITH US FOR FREE CONSULATION: INFO@FHOPEPACK.COM

FHOPE door packaging scheme be used together with shrinkage, horizontal wrapping, spiral packaging and other functions, high packaging efficiency, good product packaging status.

Different equipment is used to replace manpower, saving the cost of 365 days of labor.

Door packaging design can equipped with material automatic cutting and automatic feeding function, to achieve continuous working without stopping, operation process without operator intervention.

4.Full-Automation door packaging in procession