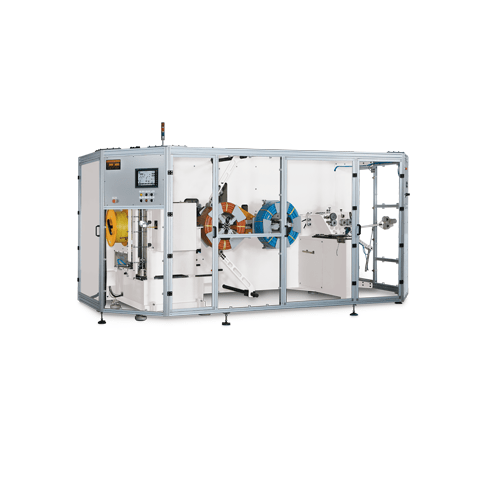

Automatic cable winding and wrapping machine--vertical

Our FHOPE GROUP is committed to providing a comprehensive packaging solution for your production. It can provide a fully automatic winding and bundling function machine; a fully automatic winding and winding function machine; or a collection and winding winding function according to customer requirements. Packing Machine. Customers can also choose between two types of automatic packaging lines, online and offline, depending on the packaging needs. FHOPEPACK provides practical packaging solutions for the packaging industry. The team is committed to the development and research of innovative, cost-effective packaging products. Packaging products address packaging issues such as loose, irregular, and the like. Our sales team, equipment maintenance team, customer team and engineering department are always ready to help you solve all the problems in the packaging process. The machine is completely in strict accordance with CE guidelines, and uses the latest and most advanced technology to complete the design and production tasks of the machine.

Main technical parameters and components:

A. Vertical tension station wire roller

Structure: Steel plate assembly and welding

Power: Geared motor

adjustable coil tension

cumulative length of steel wire: 5m-20m

Tension adjustment: The tension can be adjusted by the tension control box DC-24V power. Carrying can be controlled in two ways, and the meter shows tension. The synchronizing device automatically controls the take-up speed to avoid excessive stretching or breakage.

Safety device: The limit switch is placed at the front and rear.

The machine stops while cutting off the wires.

Anti-collision device: compression spring

B. Automatic winder

Feature:

Double winding head ensures continuous winding work.

Automatic wire feeding, winding and cutting.

The PLC can store the line volume data. When the line volume data needs to be replaced, only the storage specification needs to be read.

Automatic alarm function, automatically send an error signal when an error occurs.

Product conveying: Fixture conveying

Spare length: unit: 0.01m, automatic deceleration

The servo motor controls the rotation and is connected to the bobbin.

Operation panel and instrument: Touch screen, speed control button, emergency switch.

Machine overview:

1: meter measuring device:

With the upper and lower wheels, the length is recorded accurately on the encoder in centimeters. The upper and lower wheels are made of aluminum alloy material. The upper wheel is sprayed with ceramics to maintain the hardness during the process. The lower wheel is covered with super glue to prevent damage to the wires. One-way bearings are installed to prevent the wires from being inverted.

2. Winding station:

The air pressure automatically starts and controls the winding and retracting of the wire, automatically opening and closing, automatically stopping the winding when the preset length is reached, and then the winding head automatically opens.

3. Rocker arm:

Computer program control, servo motor motor drive.

4. Automatically cut off:

The door cutter automatically cuts the line when the coil reaches a preset length. The tool is made of special steel material and vacuum heat treatment for high hardness and long life.

5. Control system: man-machine interface, touch screen operation. The central computer system controls winding speed, coil length, alarm, speed adjustment, indicators, emergency stop and reset. The coil length, wire diameter, and line speed can be changed while the machine is running.

C. Automatic wrapping machine

Features:

1. Can be connected to the rack and production line;

2. The take-up speed is four times the manual speed;

3. It can be connected with the automatic packaging machine, automatically wrap the PVC film, and label the roll;

4. If the automatic coiler and the automatic packaging machine operate at the same time, the speed will be seven times faster than the manual.

Operation

a. Servo motor wire, the wire is more perfect and more beautiful than the manual winding wire;

b. The PLC can store the wire volume specification. When the wire volume specification needs to be replaced, only the storage specification needs to be read;

c. Automatically check the wrong function and automatically send a signal when an error occurs;

d. performance;

e. Voltage: AC380V, 3-phase, 50HZ or provided by the customer;

f. Operation direction: Enter the line from the left or choose by the customer;

g. Wire diameter: ¢1.5-12mm diameter, wire, data line, pattern line, BV/AV power line, construction line.

h. Winding shaft speed: 200rpm max.

i. Product delivery: gripping

j. Extra long: 0.01m, self-deceleration during detection;

k. Rotary shaft: Servo motor control shaft, connected to the pay-off machine;

l. Electrical circuit control: Graphical operation interface (PLC);

m. Switch and instrument of operation panel: touch screen, speed control button, emergency switch;

n. PLC has spark source node

o. PLC has a diameter test node