Mold flipper

Flipper lift table has different applications, including:

-

Processing and assembly of moulds.

-

Replacing and moving mold plug-ins.

-

Processing and assembly of engines.

-

Machining and assembly.

-

Inverting roll materials.

-

Handling of injection DIE and molds.

-

It is a versatile machine that can be used in many industrial settings for a variety of tasks.

Basic character:

Basic character:

-

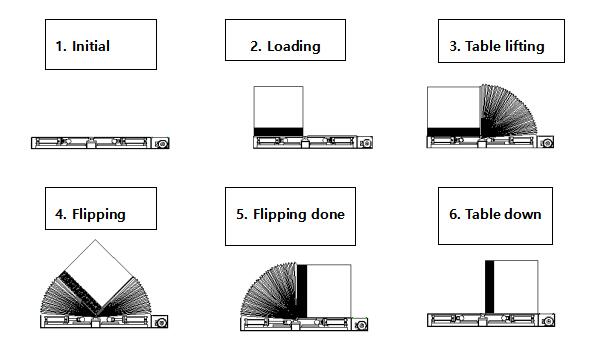

The Flipper Lift Table is a machine designed for turning molds by 90 or 180 degrees.

-

It has a heavy-duty structure and uses a high-quality hydraulic system in values and cylinder, which allows for adjustable turning speed, soft start and stop, and safety features like mechanical and electric stop block.

-

It also has a control panel or remote operation, automatic stop, smooth and accurate motion without vibration, and two-way back pressure technology.

-

The double acting hydraulic cylinders each working table, the mold can be loaded and unloaded via fork lift or crane with rope.

-

The control of the machine is pedestal mounted hydraulic power unit w/ up-down.

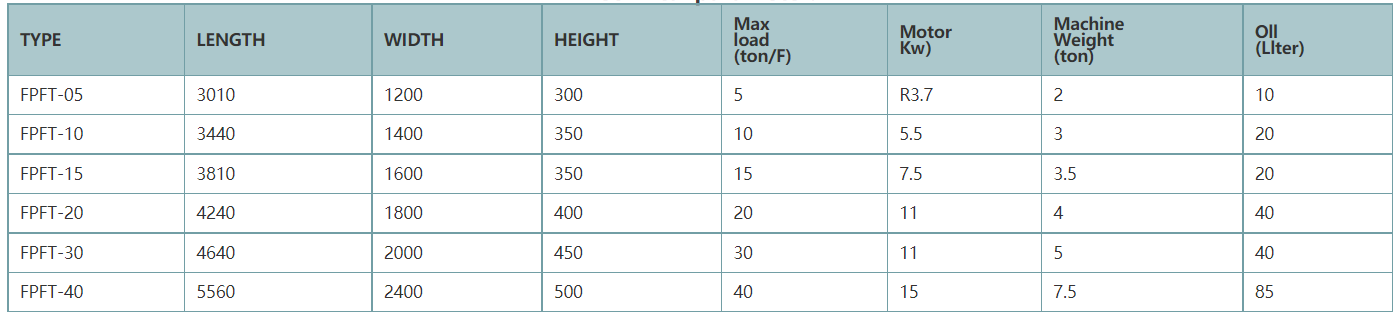

Fhope is a company that provides heavy-duty equipment for safely handling heavy molds, from 1 to 60 tons, using hydraulic systems for turning, rotating, and tilting. The equipment is designed to invert molds without any impact or damage during handling. The same machine can also be used for die flipping, with a Die flipper table that can turn the mold and die by 90 to 180 degrees.

The Mold flipper, mold turnover machine provides customers with modern solutions for the rapid changes in die, tooling, and die industrial processing in the current metal processing industry. The special turning machine allows the operator to unload the overhead crane. Fhope also provides flat-panel upender machines for customers worldwide, and these machines can be customized to meet specific needs such as payload, loading deck size, working table size, hydraulic components, cover and tilt speed.