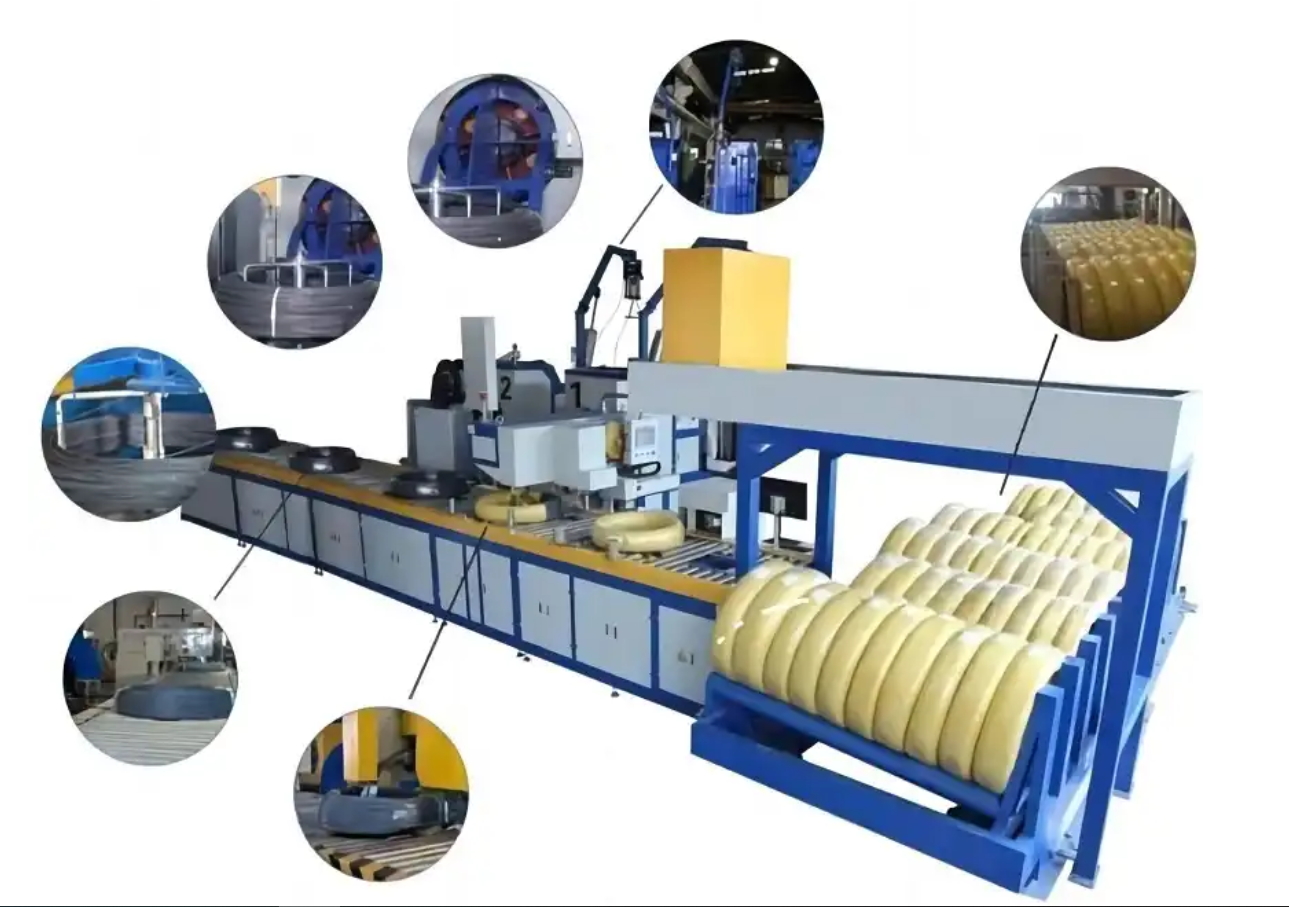

Automatic steel wire winder and packing line

Automatic steel wire packing line can operate in either manual or automatic mode, a programmable control system with a human-machine interface (HMI) for automatic operation, the ability to adjust packaging details based on input product size parameters, the ability to select and adjust packaging materials based on customer needs, the ability to use multiple packaging methods, and an automatic error reporting system. Additionally, the control cabinet can be assembled at a safe distance.

It wraps wire or cable products in packaging materials, such as plastic or paper, in order to protect them during storage and transportation. The ability to automatically set the function settings through data input and use a trolley for transporting the packaged coils suggests that this machine is highly automated and efficient, which can help to improve operational safety and work efficiency. Low maintenance costs are also a beneficial feature, as it can help to reduce downtime and keep the machine running smoothly. It is important to note that proper training and safety procedures should always be followed when operating any type of machinery to ensure the safety of the operator and those working in the vicinity.

The ability to manufacture wire coils of different specifications according to sales requirements is a flexible and adaptable feature that can help the machine meet the needs of different customers and applications.

The use of a steel external frame for strength and stability, as well as different color designs for a beautiful appearance, suggests that the machine is well-designed and visually appealing.

Using well-known brand components, such as PLCs from Siemens and Mitsubishi and pneumatic components from AirTAC, can help to ensure the quality and reliability of the machine.

The automatic alarm system that can prompt the machine failure is a useful feature that can help to identify and resolve problems quickly, which can help to reduce downtime and improve overall machine performance.

The convenience of adjustment and operation, as well as the ability to improve operational safety, can make the machine more user-friendly and safer for workers to use.

High packaging speed and the ability to meet multi-functional packaging requirements can make the machine more efficient and productive. The ability to automatically generate statistics and reports can also help to reduce packaging and labor costs, which can be beneficial for businesses.

|

Machine size |

Мах: length 8000 mm, width3000 mm, height 2000 mm |

|

Wire coil width |

100-300mm |

|

Inner diameter |

250-550mm |

|

Outer diameter |

400-700mm |

|

Weight |

10-50Kg |

|

Straps |

2/4 |

|

Conveying speed |

1 - 3 m/min |

|

Voltage |

AC 220/380V, 50/60 Hz |

|

Machine size |

Мах: length 8000 mm, width3000 mm, height 2000 mm |

|

Wire coil width |

100-300mm |

|

Inner diameter |

250-550mm |

|

Outer diameter |

400-700mm |

|

Weight |

10-50Kg |

|

Straps |

2/4 |

|

Conveying speed |

1 - 3 m/min |

|

Voltage |

AC 220/380V, 50/60 Hz |