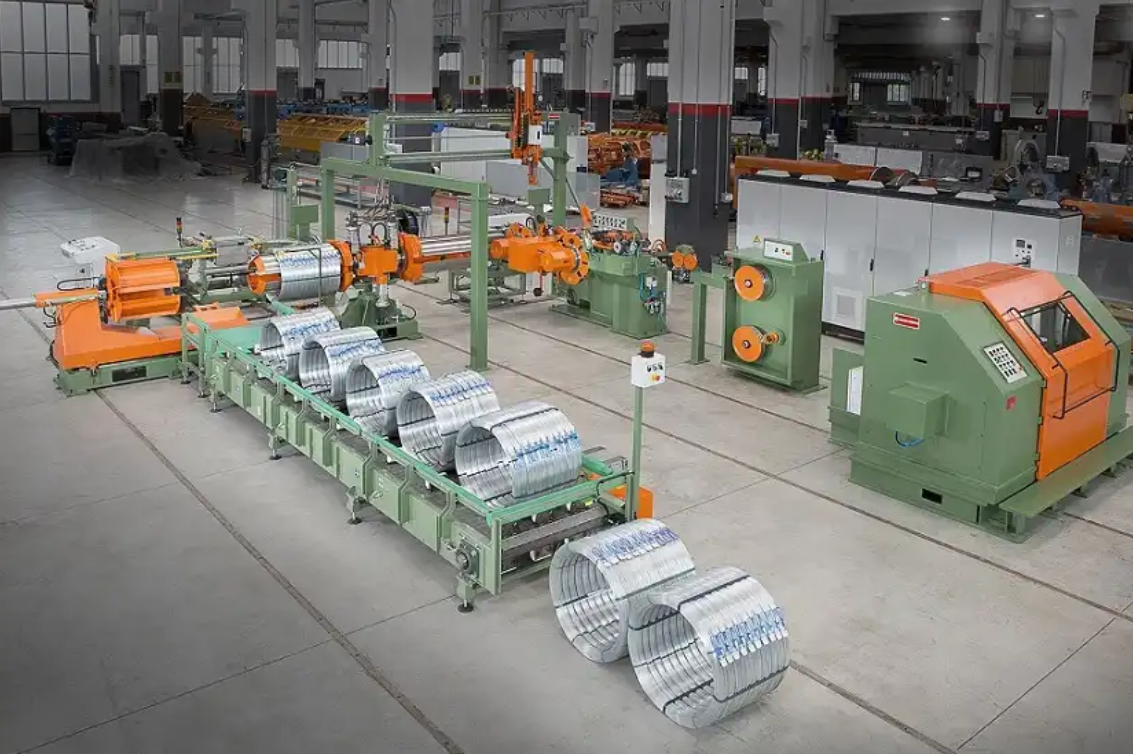

Automatic steel wire winder and strapping machine

The packaging line is designed with the latest technology and meets CE standards, making it a highly advanced and efficient solution for the steel wire industry. The FHOPE team is dedicated to continuous innovation and design, working to create the most efficient machines and solve problems related to manpower shortages and packaging costs. The FHOPE Group has a sales, design, quality, and after-sales department that is ready to help customers design the best fully automated packaging system to meet their needs.

Using a fully automated packaging system like this can help to improve the efficiency and productivity of a steel wire manufacturing or storage facility. It is important to follow proper safety protocols and maintenance procedures when using this type of machinery to ensure safe and reliable operation.

A. Vertical tension wire accumulator

The vertical wire storage tension system that is used to store wire in a vertical orientation. The tension system is assembled and welded using steel plates, and the tension in operation is adjusted using a control cabinet with a DC-24V power supply. The system has a cumulative wire length of 5m-20m and uses a deceleration motor to control the speed of running and avoid over tension or wire breakage. Multiple limit switches are also used to ensure safety, and the machine will stop in an emergency if the wire breaks.

Using a wire storage tension system like this can help to ensure that wire is stored safely and efficiently in a vertical orientation. It is important to follow proper safety protocols and maintenance procedures when using this type of equipment to ensure safe and reliable operation.

B. Automatic Coiling Machine

It uses a programmable logic controller (PLC) to store wire specifications and automatically feed, wind, and cut wire. The PLC is able to read stored specifications when they are unchanged, which can help to improve efficiency and reduce the need for manual input. The system also has a double winding head for non-stop working and an automatic alarm system that activates in case of an abnormal event during operation.

The use of a servo motor to control transverse movement and a human-machine interface (HMI) touch screen with an operation panel and speed control button can help to make the system easy to operate and adjust. An emergency switch is also included for added safety. It is important to follow proper safety protocols and maintenance procedures when using this type of machinery to ensure safe and reliable operation.

It is to measure and count the length of wire or other materials. The counter features an automatic up and down adjustable encoder reel that provides accurate counting to the centimeter. The upper and lower wheels of the counter are made of aluminum alloy material, while the lower wheels are coated with strong polyurethane (PU) to prevent deformation and damage to the wire. The lower wheels are also made of ceramic and are treated for hardness to ensure durability and performance.

Using a length meter counter like this can help to accurately measure and count the length of wire or other materials, which can be useful for various applications in manufacturing, construction, and other industries. It is important to follow proper safety protocols and maintenance procedures when using this type of equipment to ensure accurate and reliable operation.

The system includes automatic wire feeding and clamping, as well as automatic start coiling making. A servo control arranging system is used to control the shape of the coil, and the nose is precisely positioned for start and stop, as well as coil strapping positioning. When the predetermined length is reached, the system will automatically stop and the coiling head will open automatically.

Using a wire coiling system with these features can help to improve the efficiency and accuracy of the coiling process, which can be beneficial for various applications in manufacturing and other industries. It is important to follow proper safety protocols and maintenance procedures when using this type of machinery to ensure safe and reliable operation.

The cutter is made of special steel that has been processed using vacuum heating, which can result in higher hardness and a longer service life. The cutter is designed as a door cutting machine, which means that it will automatically cut off the wire when the bobbin reaches a predetermined length.

Using a cutter like this can help to improve the efficiency and accuracy of the wire coiling process, as it allows for precise cutting of the wire at a predetermined length. It is important to follow proper safety protocols and maintenance procedures when using this type of equipment to ensure safe and reliable operation.

C. Automatic coil strapping machine

When the coil is moved to the strapping position, the strapping device tightens and seals the PP belt around the coil. The device is also able to automatically adjust the tension to ensure safe hot welding at the strapping positions.

Using a strapping device like this can help to ensure that wire coils are securely bound and able to withstand the rigors of storage and transportation. It is important to follow proper safety protocols and maintenance procedures when using this type of equipment to ensure safe and reliable operation.

The use of PLC program control and automatic positioning can help to automate the process and reduce the need for manual input. The adjustable tension feature allows the system to accommodate different wire coil sizes, while the ability to strap in multiple places per coil can help to ensure that the wire coils are securely bound. It is important to follow proper safety protocols and maintenance procedures when using this type of machinery to ensure safe and reliable operation.

The machine is able to automatically perform all the strapping actions, which can help to improve efficiency and accuracy. The belt distributor and accumulator are placed in a fixed position, which makes the machine easy to operate.

Using a strapping machine like this can help to ensure that wire coils are securely bound and able to withstand the rigors of storage and transportation. It is important to follow proper safety protocols and maintenance procedures when using this type of machinery to ensure safe and reliable operation.

Technical date:

Strap width 10mm

Strap thickness 0.8 mm

Type of strap PP belt

Strap quality Smooth /High quality polyester strap

Type of joint By friction - vibration

Joint location The strapping is performed in the front part of the wire coil.

Joint efficiency Approx. 75-90% of the breaking load of the strap.

D. Automatic wire coil unloading machine

It takes wire coils from the strapping position and stack them for pallet unloading. The device uses automatic program control to keep the crane and guide rail running smoothly and to complete the final step of the automation packaging line.

Using an automatic device like this can help to improve the efficiency and accuracy of the wire coiling and strapping process, as it allows for automated handling of the bound wire coils. It is important to follow proper safety protocols and maintenance procedures when using this type of machinery to ensure safe and reliable operation.