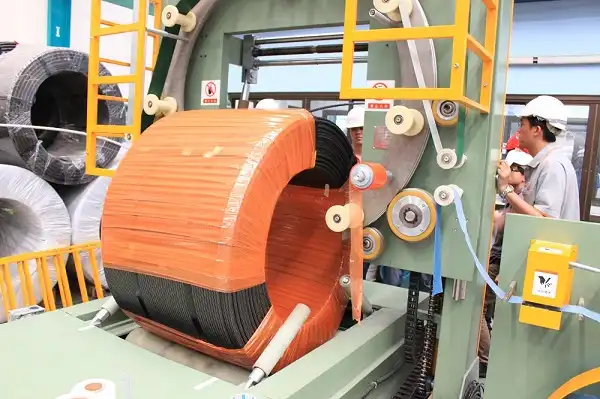

Wire coil wrapping machine FPW-500

FPW-500 series wire coil wrapping machine seems like a great investment for companies looking for a reliable and efficient solution for packaging wire coils. With its convenient loading and unloading trolley and high-quality electrical components, it can help streamline the packaging process and save on energy and maintenance costs.

The fact that all electrical components are designed for high speed, gentle handling, and high reliability with lower maintenance and energy costs is impressive. This means that the machine is not only efficient during the packaging process but also cost-effective to operate and maintain over the long term.

The machine's ability to pack wire width 100-500mm with the help of a crane for loading and unloading from the top makes it suitable for handling heavy and large wire coils.

The use of an eye through coil ID with 360-degree turning enables flexibility in the packing process, which can be adjusted to meet specific packaging requirements. This feature can also contribute to the low maintenance required by the machine.

The machine's high efficiency packing speed, which can replace 3-4 man power, is impressive, as it can help companies save on labor costs and improve productivity. Additionally, the package's appearance is nice, and it is good for sea shipping, which is crucial for companies that need to transport their products over long distances.

Considering the machine's features and the investment cost, it is clear that the FHOPE FPS-500 wire coil packing machine is a good value proposition for businesses looking to improve their packaging processes. With a potential investment return in 1-2 years, the machine offers an opportunity to optimize productivity, reduce labor costs, and enhance the quality of packaging, ultimately leading to improved profitability for the company.

Parameters:

Coil Packing Machine FPW-500

Voltage (V/Hz) 380v 50Hz 3Phase

Power (KW) 3.5kw

Steel wire coil ID(mm) 300-700

Steel wire coil OD(mm) 700-1300

Steel wire coil width(mm) 50-500mm

Steel wire coil Weight(Kg) 40-1500kg

Packing material PVC/LDPE/LLPE/PAPER/HDPE

ID:50mm OD:100-450mm Width:100-120mm

Overlapping rate 10%-90%

Air supply. 4-6kgf/m2

The use of a crane for loading and unloading the coil, along with the stationary operation of the machine, provides a safe and efficient packaging process. The C-hook and mobile coil trolley are also useful accessories that can help move the coil to the packing station easily.

The machine's ability to move back and forth and the use of limited sensors for positioning management is impressive, as it ensures the accuracy of the packaging process. The option to keep the machine on floor rails for multiple packing stations is also a great feature that can improve the machine's flexibility and productivity.

The combination of supportive rolls with the packing station is also a useful feature that allows for both stationary and mobile options. Overall, the FPW-500 series wire coil wrapping machine seems like a versatile and efficient solution for packaging wire coils. With its flexible design and high-quality electrical components, it can help companies improve their packaging process and save on maintenance and energy costs.

Features:

-

Automatic wire coil wrapping with packing material length checking ensures that the packing material is used optimally, and no excess or insufficient material is used.

-

The machine can handle different types of packing materials, and the next packing material is selected according to the wrapping station type.

-

The machine has supportive roller PU covering & passive friction wheels and integral mould structure devices to prevent skidding and ensure that the package object is stable and tidy.

-

Different packing materials can be adopted, making the machine versatile.

-

The main board up and down adjustment is done by motor with gear, making the machine easy to adjust.

-

The overlap extent and tension degree of the packing material can be regulated as per customer's requirements.

-

The mechanical hand device is used for feeding and cutting the packing material automatically, making the process more efficient.

-

The trolley can be moved in and out of the wrapping station with precise positioning automatic, making the process more accurate.

-

The machine is easy to operate, and even non-skilled operators can use it.

-

The special cutter with a cylinder can cut various kinds of packing materials, making the machine versatile.