Wire coil wrapping machine FPW-800

Features:

Features:

-

The ability to switch between automatic and semi-automatic modes allows for greater flexibility in operation and can help increase efficiency in the packing process.

-

The availability of multiple types of packing materials can provide users with a range of options for their specific needs.

-

The use of anti-wear polyurethane active and passive friction wheels and integral mould structure devices can help improve the stability and tidiness of the packed object, and also increase safety during operation.

-

The ability to use different packing materials, such as woven belt, compound paper, and stretch film, can help meet the diverse packing needs of different types of wire coils.

-

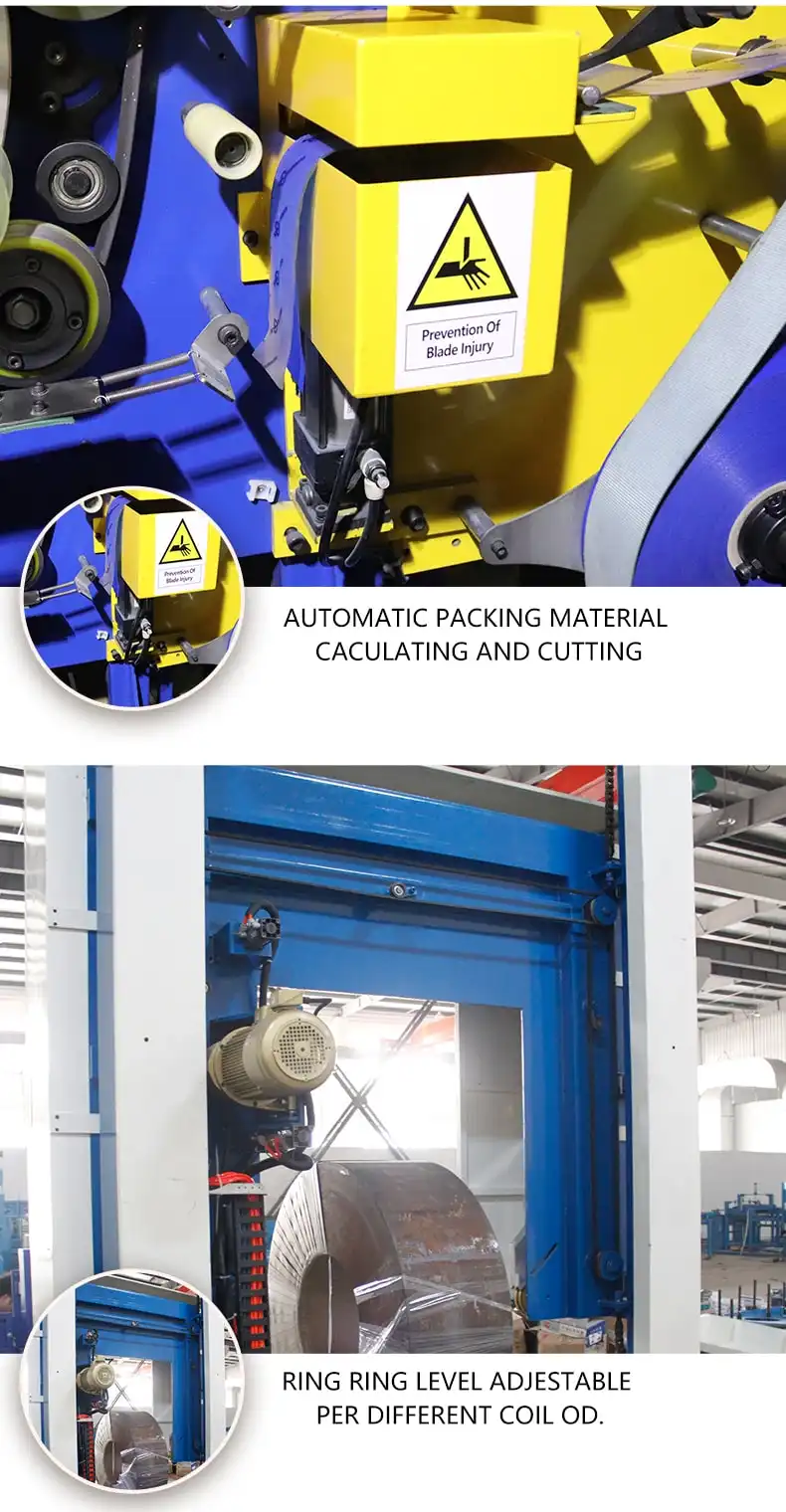

The ability to adjust the ring center height based on the wire coil specification can help ensure that the coil is packed securely and correctly.

-

The ability to regulate the overlap extent and tension degree of the packing material can provide users with greater control over the packing process, and can help ensure that the packed coil is of high quality.

-

The mechanical hand device can help automate the feeding and cutting of packing materials, which can help improve efficiency and reduce the need for manual labor.

-

The optional pushing-out device can make it easier and more convenient to carry out the packed wire coil.

-

The optional labeling device and side press roller can help improve the accuracy and consistency of the packing process, and can help ensure that the packed coil meets the desired quality standards.

-

The special cutter with cylinder can cut a variety of packing materials, which can increase flexibility in the packing process.

Parameters FPW-800:

Voltage (V/Hz) 380v 50Hz 3Phase

Power (KW) 3.4kw

Steel wire coil ID(mm) >500

Steel wire coil OD(mm) 800-1400

Steel wire coil width(mm) 300-800mm

Steel wire coil Weight(Kg) 200-3000kg

Packing material PVC/LLDPE/PE/PAPER/HDPE

ID:50mm OD:100-250mm Width:100-300mm

Overlapping rate 10%-90%

Air supply. 4-6kgf/m2

The flexibility and capabilities of the packing machine suggest that it is designed to provide users with a high degree of customization and adaptability to meet their specific needs and requirements.

-

The ability to design the machine for any size of steel wire coil provides users with a high degree of flexibility and customization options.

-

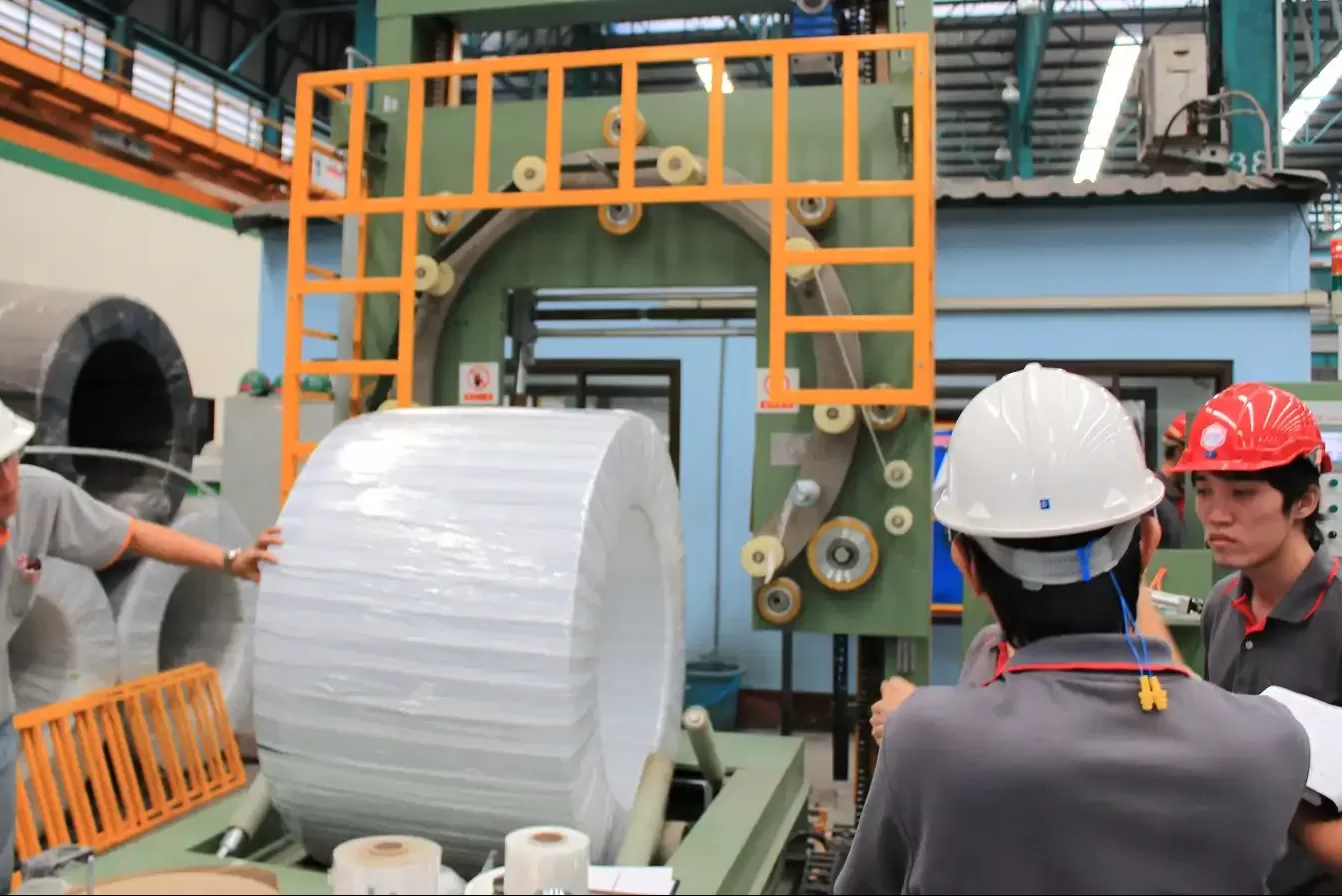

The use of a crane to load the coil can help streamline the packing process and reduce the need for manual labor.

-

The stationary operation of the machine can help improve safety during operation and increase efficiency in the packing process.

-

The use of a C-hook and mobile coil trolley can help facilitate the movement of the coil to and from the packing station, which can further enhance efficiency.

-

The ability to use a coil tilter or coil tipper can provide users with additional options for loading and positioning the coil for packing.

-

The use of limited sensors attached to the packing station can help manage the positioning of the coil during the packing process, which can help ensure accuracy and consistency.

-

The ability to keep the machine on floor rails and move it between packing stations can provide users with greater flexibility in the packing process and can help improve efficiency.

-

The combination of supportive rolls with the packing station can help ensure that the coil remains stable during packing, regardless of whether the rolls are stationary or mobile with the truck.